Our History

High-quality high-voltage construction since 1977.

driven to succeed

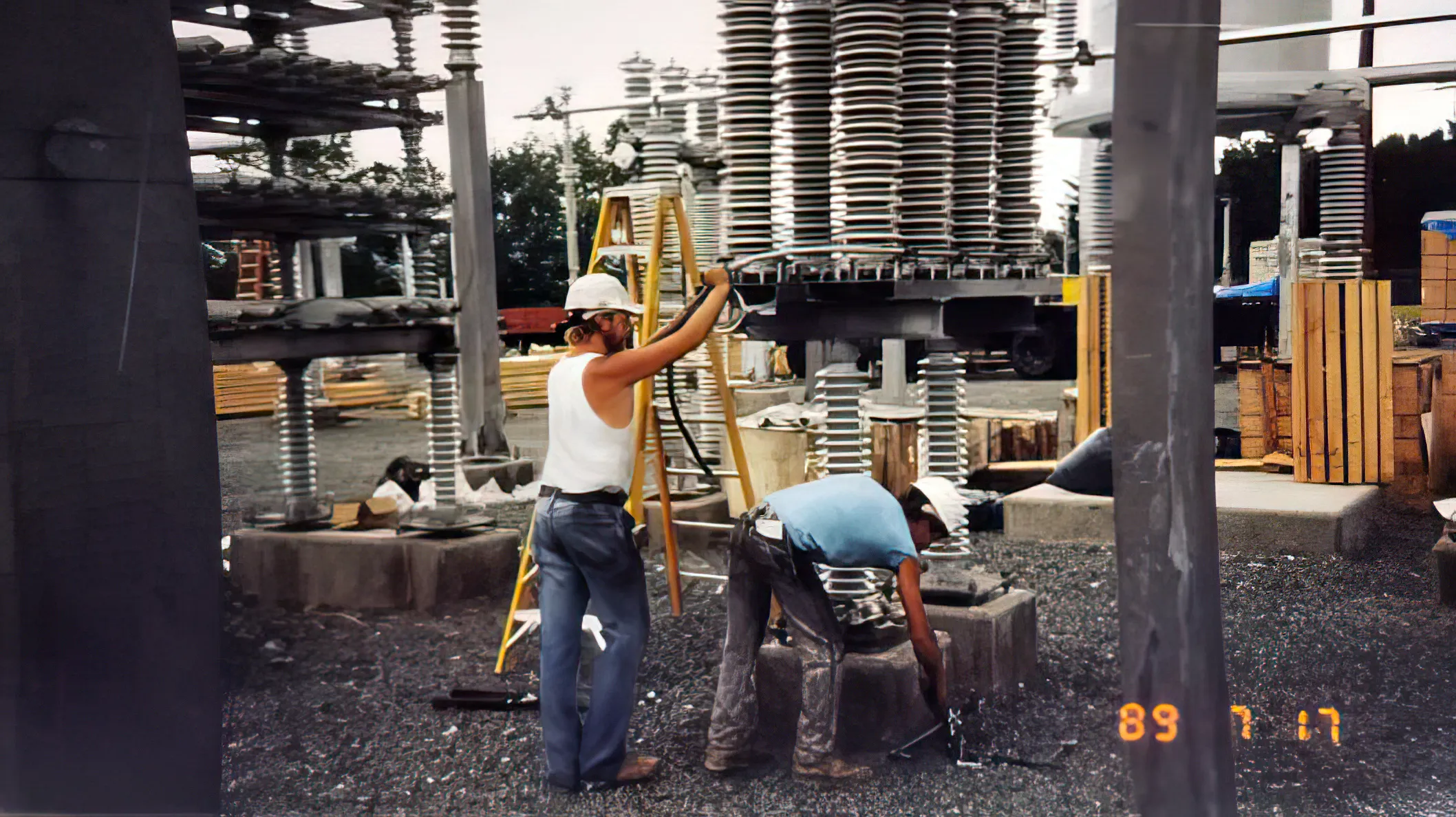

National Conductor Founder, Scott Zahn, began his career in the high-voltage construction industry as a young man. He worked as a groundman, assisting linemen with setting poles, stringing power lines, and completing various other tasks. After working on his first substation, Scott saw the demand for aluminum welders in the substation arena and decided to learn welding himself. After learning to weld and working as a welder for hire, he officially established National Conductor in 1977.

From Aluminum Welding to Turnkey Solutions

From the very beginning, National Conductor’s foundation has been aluminum welding. Scott purchased his first TIG welding machine and truck and traveled around the Midwest to weld aluminum bus for the local electrical contractors that were building substations. Once he established himself in the industry, Scott began working his way into other facets of substation construction. He started with having his crews set the steel structures and high-voltage equipment. Eventually, Scott was able to offer turnkey projects to his clients, with his crews handling electrical aspects, from installing conduits to the installation and terminating of control and power cable.

The Power Plant Division Flourishes

In the late 1980s, Scott reached out to the power plants for which he constructed substations and asked how isolated phase bus duct was installed.

He learned that this also was an aluminum bus duct that runs from the main generators to the step-up transformers outside the plant. And, that this was typically installed by the manufacturer or plant employees at nearly all of the power plants in the United States. Knowing this—and already having immense experience in aluminum welding and bus fabrication—Scott saw the opportunity to expand National Conductor’s services and take on new work. National Conductor’s Power Plant Division was created.

National Conductor took the power plant industry by storm as the first installation contractor of isolated phase bus duct (outside of manufacturers and plant employees). Scott and his team worked their way from the IPB manufacturers to power plants across the country promoting their new services. National Conductor quickly became known as a reputable and high-quality construction company, leading to the company replacing the isolated phase bus duct on the Hoover Dam–one of the company’s greatest achievements.

Good Work Driven By Strong Values

National Conductor has become one of the most respected electric utility contractors in the United States through living and working by the three simple values that founded the company: honesty, quality, and safety. These values are what enable us to continue to provide quality work, and why we stand behind a proven track record of safety, effective time and cost management, and longstanding relationships with our clients and subcontractors.

Join The National Conductor Team

We build Substations, Switchyards, Wind Farm Collector systems and install and maintain Isolated Phase Bus Duct nationwide. We are a signatory IBEW contractor whose home union is Local Union 160, Minneapolis, MN.

What We Do

National Conductor is one of the top high-voltage construction companies in the industry. With a team of professional employees whose combined knowledge exceeds 400 years of experience, National Conductor has completed more than 1,000 high-voltage projects across the nation.

Our projects include:

Substations

Switchyards

Wind farm collector systems

Bus and wire systems

Static VAR systems

Isolated phase bus duct (IPB) installation

IPB maintenance and inspection